1. Get A Free Inspection & Quote

2. Repair With Confidence

3. Ready For Hard Work

Expert Suspension Cylinder Repairs For Heavy Equipment

Off-highway trucks operate in harsh environments under constant load. Over time, front and rear suspension cylinders are exposed to wear, corrosion, and internal degradation.

When suspension performance changes, the next step is often unclear. Some cylinders are labelled beyond repair without full inspection, while others are partially repaired and fail again shortly after returning to service.

Clear information is needed before the right decision can be made

Don’t Compromise on Suspension Cylinder Safety and Performance

When your suspension cylinders fail, you risk not only expensive repairs but also the safety of your operations.

Our comprehensive inspections help you identify the issue early, so you can make the right call and keep the off-highway truck suspension functioning smoothly.

- Suspension cylinder leaks decreasing truck handling performance.

- High costs for new suspension cylinder strain budgets.

- Uncertainty of extend of suspension cylinder condition.

- You've been told it's not repairable

We understand the limited access to expert insight and options is frustrating.

Now you can get help.

Get A FREE Inspection & Quote - For Off-Highway Truck Suspension Cylinders

Restore Suspension Condition & Cylinder Performance...

A Clear, Inspection-Led Way Forward

Experience cost-effective repairs that bring your suspension cylinders back to life, ensuring your equipment performs reliably while saving you money.

- Expert dismantling and assembly using specialised equipment.

- Full inspections ensure accurate diagnoses

- Quotes with a clear plan and cost-effective solutions

- Expertise from over 33 years of heavy equipment hydraulic cylinder repairs

Get A FREE Inspection & Quote

Why We Can Help You:

31+ Years Of Service Solutions

Time-tested solutions, proven over and over again by our customers

Professional Team Service

Experts specialising in hydraulic cylinder servicing

10,000's+ Cylinders Serviced

Expert knowledge and experience

Get The Suspension Cylinder Service That Has Helped Companies All Over Australia

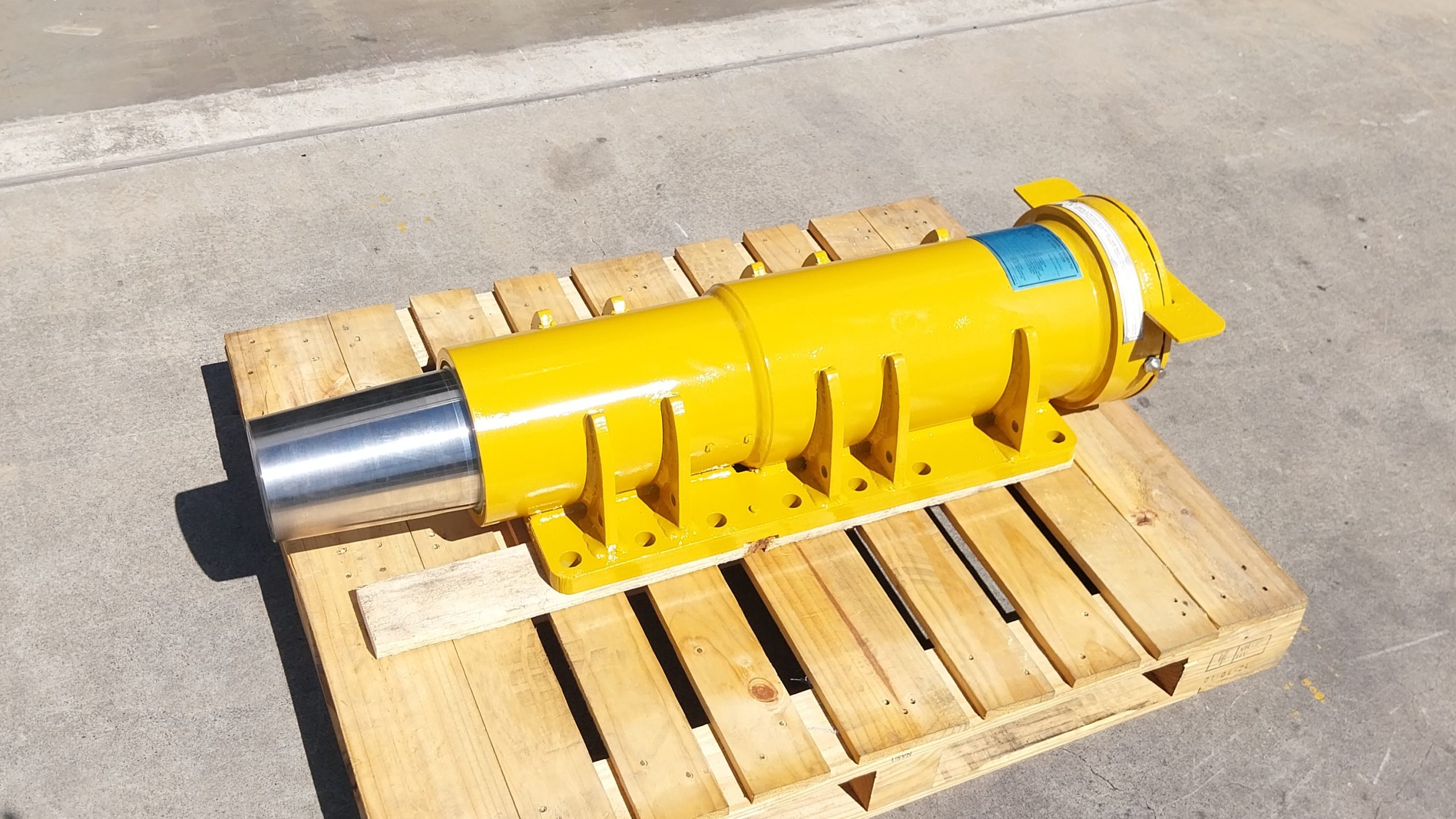

From Repairs to Reman – Front & Rear Off-Highway Truck Suspension Cylinders Services

Every service process below is designed to achieve the same outcome: Maintaining ride height, nitrogen pressure retention, and controlled suspension response under operating conditions.

The difference is the condition of the front or rear suspension cylinder and the level of work required to restore it to specification.

Disassembly & Assembly:

Suspension cylinders are dismantled and assembled using a dedicated off-highway suspension cylinder bench. The full control for positioning ensures correct procedures, alignment and prevent seal damage.

Inspection:

All components are inspected after dismantling to assess wear, surface condition, and serviceability. This confirms the true condition of the cylinder and supports informed repair or replacement decisions.

Resealing:

Worn seals and sealing elements are replaced using suitable seal kits. Correct sealing restores pressure retention and prevents oil and nitrogen loss under operating conditions.

![Off-highway_Truck_Suspension_Cylinder_Cap_Repairs[1] Off-Highway Truck Suspension Cylinder Struck Repairs End Cap Repair, Rebuild, Reclaim, Metal Spray, Regrind, Re-Man by A1 Hydraulic Engineering](https://a1hydraulics.com.au/wp-content/uploads/2026/02/Off-highway_Truck_Suspension_Cylinder_Cap_Repairs1-scaled.jpg)

Part repairs & Reman:

Worn or damaged components such as heads, spigots, and internal parts are repaired or remanufactured where serviceable. This extends component life and avoids unnecessary replacement.

![Off-highway_Truck_Suspension_Cylinder_Rod_A1_Hyd[1] Off-highway truck suspension cylinder strut rod repairs and re-chroming by A1 Hydraulic Engineering](https://a1hydraulics.com.au/wp-content/uploads/2026/02/Off-highway_Truck_Suspension_Cylinder_Rod_A1_Hyd1-scaled.jpg)

Rod Rechroming

Damaged or corroded rods are reconditioned by stripping, re-chroming, and grinding back to specification. A high quality rod surface finish is critical for seal life and suspension performance.

![Off-highway_Truck_Suspension_Cylinder_Valves_A1[1] Off-Highway Truck Suspension Cylinder Struct Repairs Recommended Replacement Parts A1 Hydraulic Engineering](https://a1hydraulics.com.au/wp-content/uploads/2026/02/Off-highway_Truck_Suspension_Cylinder_Valves_A11-scaled.jpg)

New Components

Certain suspension cylinder components are designated as recommended replacement parts. These parts are identified during inspection and replaced as required to maintain reliability, service life, and correct suspension performance.

3 Simple Steps to Restore Your Off-Highway Truck Suspension Performance

Experience hassle-free repairs and maximise uptime with our clear, evidence-driven assessment and repair process.

1. Get A Free Inspect & Quote

Have your suspension cylinder dismantled and inspected at no charge, with a clear, no-obligation repair scope provided before any work proceeds.

2. Repair With Confidence

After inspection, you receive a detailed repair scope outlining required work and recommendations.

Once approved, the suspension cylinder is restored in accordance with the confirmed plan.

3. Ready For Hard Work

The suspension cylinder repairs and assembly are completed, ready for installation and reliable performance in service.

Get A FREE Off-Highway Truck Suspension Cylinder Inspection & Quote Now!

Get A FREE Inspection & Quote For Off-Highway Truck Suspension Cylinders

Need your suspension cylinder resealed or repaired?

Have it dismantled and inspected at no charge, with a clear repair scope provided before any work proceeds.

We assess condition, identify required repairs and recommended replacement parts, and provide a clear plan. Experience suspension cylinder repairs with confidence.

Frequently Asked Questions

Yes. Many suspension (strut) cylinders can be repaired if critical components remain within service limits. Full dismantling and inspection confirm whether resealing, component repair, or remanufacture is suitable, or whether replacement is required.

The most common causes include seal wear and poor rod surface quality. Loss of pressure can result in dropping ride height, uneven load support, and dangerous suspension behaviour.

Typical signs include oil leakage, dropping ride height on one corner, uneven suspension response, or visible rod corrosion or scoring. Inspection is required to confirm internal condition and serviceability.

A repairs can include full dismantling, inspection, rod rechroming, replacing of recommended parts, new seals, and controlled assembly.

Turnaround time depends on the condition of the cylinder and the level of repair required. Once inspected, a clear repair scope and timeframe are provided before work proceeds.

Yes, by all means.