There’s nothing small about a leaking hydraulic cylinder on an excavator, loader, or dozer. That slow drip isn’t harmless…

It’s a red flag.

On an earthmoving or mining site, it’s the difference between meeting production targets and watching idle machines stack up costs by the hour.

Every unscheduled stoppage triggers a ripple effect: personnel waiting, subcontractors delayed, and penalties creeping closer.

For earthmoving companies, this isn’t just about general heavy equipment maintenance. It’s about protecting uptime and profits.

And one of the smartest ways to stay ahead is by handling hydraulic cylinder resealing before it turns into costly component failure.

The Real Cost of Ignoring a Hydraulic Leak

Hydraulic oil doesn’t just vanish. Every drop that leaks is a loss in three directions:

- Lost productivity: machines sidelined when they should be pushing dirt or loading trucks.

- Escalating costs: a seal job that could have been done in days turns into a full cylinder rebuild or even replacement.

- Environmental impact and safety risks: oil leaks means mess, regulatory headaches, and reputational damage.

Here’s what it comes down to: when you ignore a hydraulic cylinder leak until it becomes a major problem, you’re looking at emergency repair costs that are 400% higher than routine maintenance. The reality is that delaying repairs always costs you more in the end.

The 5 Key Steps in Hydraulic Cylinder Resealing

You When done right, resealing a hydraulic cylinder restores both performance and longevity.

At A1 Hydraulic Engineering, these are the steps we guide you through:

1. Inspection

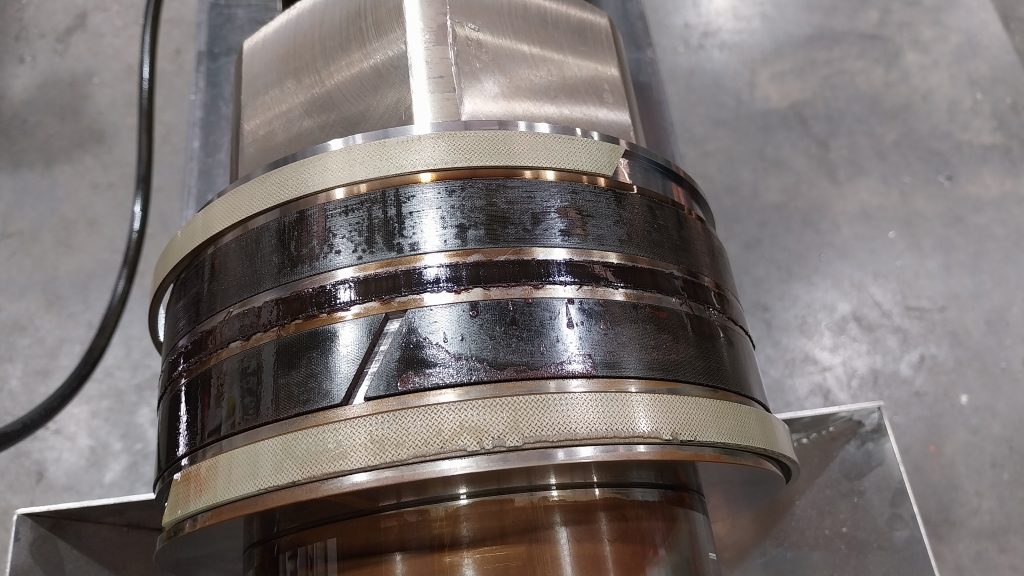

Every job starts with stripping the hydraulic cylinder down and checking for problems or damages. If the damage is too severe, resealing alone won’t hold, and pretending otherwise only guarantees another failure.

2. Cleaning

Contamination is the silent killer of hydraulics. Before fitting new seals, parts must be cleaned to stop dirt and debris from creating more problems.

3. Seal Kit

Using genuine seal kits means it’s straight forward. But if you’re opting for after-market, then it’s important to know that not all seals are created equal. Using cheap or mismatched seals in high-pressure earthmoving in mining machines is a shortcut to another failure. Only select seals from reputable-known brands for your machine’s hydraulic cylinder.

4. Assembly

Resealing isn’t about forcing rubber into grooves. Seal installation, lubrication, tightening torques, and assembly techniques all decide whether the hydraulic cylinder will runs leak-free once again or fails shortly after.

5. Testing Under Pressure

Pressure testing a resealed hydraulic cylinder, before the machine is back onsite, is the best way to check your resealing work. As always, be aware of the dangers of high pressure oil leaks. Read first the valuable information in the machine’s own manual.

The Upside of Proactive Resealing

Companies that reseal cylinders before failure see measurable benefits:

- Fewer unplanned stoppages on machines

- Longer service life from existing equipment

- Lower total maintenance spend across the fleet

- A safer, cleaner site free from hydraulic oil spills

Ready to Get Ahead of Hydraulic Downtime?

Earthmoving, mining and civil projects are won on productivity. And productivity is won or lost on the reliability of your heavy equipment. Don’t let a hydraulic leak become the weak link in the earthworks project.

At A1 Hydraulic Engineering, we help earthmoving and mining operators across Australia keep their machines running strong. Whether you’re running excavators, dozers, graders, or loaders, we specialise in fast-turnaround reseals, expert repairs, and reman of hydraulic cylinders.

If your hydraulic cylinders are due for attention, don’t guess. You can get a free quote today. Let’s inspect them properly and show you exactly what they need so you can make the right call.

Get Your Free Hydraulic Cylinder Quote

Call us today on 07 3800 8721 and get a FREE quote.

Written by The A1HE Team

Date: 26.08.2025