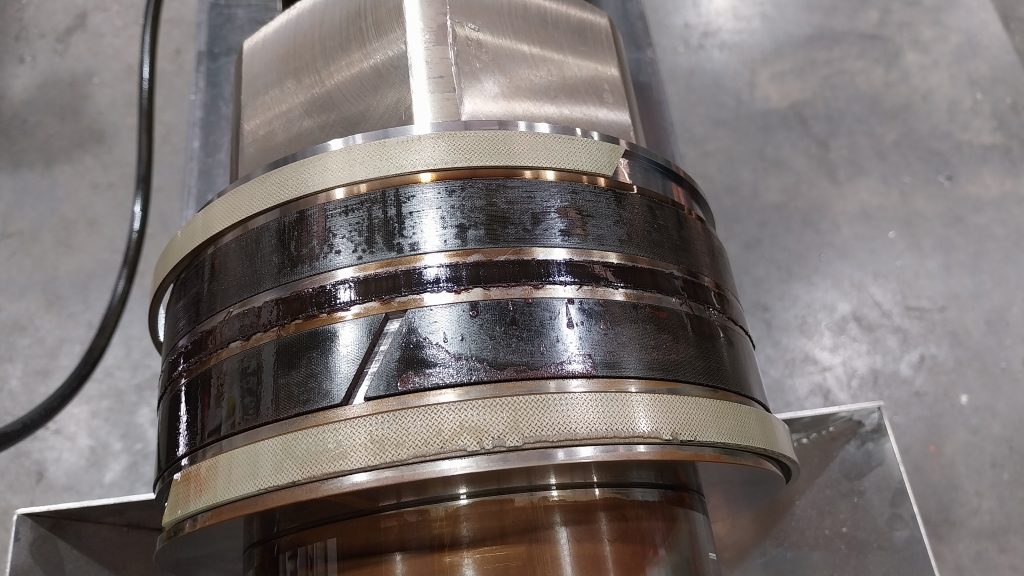

When you’re running an excavator day in and day out, hydraulic cylinders are the silent workhorses behind every move your machine makes. From digging to lifting to demolition, each cylinder plays a critical role in keeping your heavy equipment operating smoothly. But like all hard-working components, these cylinders need proper care to keep running at their best. Neglecting these directly affects your productivity and profits. Let’s break down the 3 hydraulic cylinders, the conditions they face, the condition they could be in, and what to do about it.de Boom Cylinder: The Heavy Lifter The boom cylinder lifts and lowers the boom, the main arm of your excavator. It’s responsible for handling the heaviest loads. Operating conditions: The boom cylinder operates under extreme pressure, especially when lifting heavy materials or digging deep. Over time, seals can wear out, and leaks and ‘drift’ or ‘creep’ can develop. ‘Drift’ or ‘creep’ is when the boom cylinder, or cylinders, can’t maintain the pressure needed to hold the boom in place. This results in the boom to slowly drop over a short time, especially when holding a load. Active servicing the boom cylinders avoids losing lifting power and slowing down your productivity. . Arm Cylinder: The Reach The arm cylinder (aka: stick , dipper, crowd) extends and retracts the arm, controlling how far your excavator can dig. It faces a lot of wear when digging into hard soil or rock. This constant movement under load can wear seals and cause leaks. At times, excavators are used like a crane. And just like the boom, the arm cylinder it can dovelop ‘drift’ or ‘creep’ too. Why it’s important to service: A sluggish or leaky stick cylinder means losing control and precision, making it harder to dig efficiently. Keeping this cylinder in top shape ensures smooth, responsive operation every time. Bucket Cylinder: Your Material Mover The bucket cylinder controls not only the bucket, but every every other attachment the operator uses. The operating conditions it is exposed to are harsh: Heavy loads, constant movement, and harsh material contact can damage the chrome rod and seals worn quickly. On top of this, when using a hammer attachment for rock or concrete breaking, the bucket cylinder is taking a lot of punishment. Massive rock-breaking energy goes to this ram while it’s holding the hammer attachment in position. Why it’s important to service: A leaky bucket cylinder leads to slower cycle times and less force, dragging out your work and reducing productivity. Maintaining this hydraulic cylinder ensures your bucket moves as fast as you need it to, without leaks or power loss. How To Get Hydraulic Cylinder Help We specialise in servicing hydraulic cylinders for the mining, earthmoving, and heavy equipment industries, ensuring your equipment operates at peak performance with minimal downtime. Contact us today to have your hydraulic cylinders serviced by our expert team, allowing you to focus on maximising productivity and efficiency in your operations. Contact us on 07 3800 8721 and a friendly team member will help you get the best solution for you GET YOUR FREE QUOTE NOW Written by The A1HE Team Date: 27.09.2024